Home

External Visual Inspection

External Visual Inspection |  |

|

| External Visual Inspection

External visual inspection is a process of verifying the attributes of parts such as components condition, part markings, evidence of a secondary coating, lead conditions, dimensions and surface quality. Visual inspection is performed per SAE AS5553 and MIL-STD-883 Method 2009.9 and on a sample of parts from a given lot base on the sample according to the ANSI ASQE Z1.4 Table II−A.

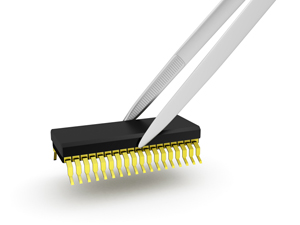

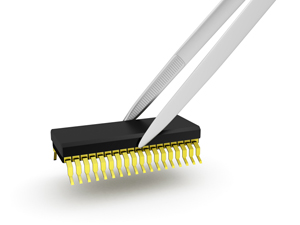

Visual Inspection is a term used for inspecting electronic components under a microscope to determine if a device has been altered from its original state. During this process a device may show signs of non conformance or inconsistencies that help determine if a device has been used or if a device is new and original. This process is normally performed by a Components Test Lab or Test House for short. This process is a non-destructive and devices can be used afterwards. There are so many things to look for during a visual inspection. Here are some things generally looked for during a visual inspection of IC Devices:

Substrate Condition |

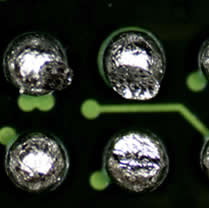

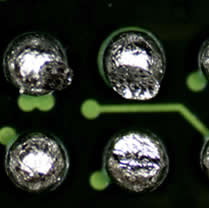

BGA Condition |

Package Condition |

|

• Damaged Substrate

• Scratched Substrate Through BGA

• Left-Over Residue

• Foreign or Displaced Material |

• Ball Formation

• Scratches

• Residue

• Smashed BGA

• Missing BGA

• Excess Solder Material

• Foreign or Displaced Material

• Scratched Substrate Through BGA |

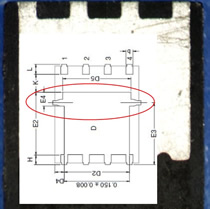

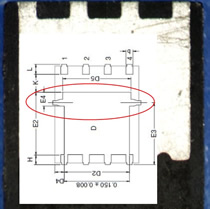

• Physical Dimensions

• Package Construction

• Construction Defects |

| |

|

|

Device Markings |

Pin Indicator |

Body Inspection |

|

• Consistently Printed Device Markings

• Double Printed Markings

• Marking Placement

• Ghost Markings

• Faded Device Markings

• Marking Alignment

• Font Consistently Printed

• Illegible Markings

• Marking Orientation

• No Markings

• Laser Burns |

• Texture of Pin Indicator

• Consistent Orientation

• Foreign or Displaced Material Inside Pin

• Coating Inside Pin

• Overspray Inside Pin

• Fibers from Cleaning Inside Pin

• Country of Origin

• Pin Size

• Pin Depth |

• Sanding Marks

• Secondary Coating

• Pull Marks

• Tool Marks

• Flaking

• Scratches

• Molding Texture

• Foreign or Displaced Material

• Contamination

• Mold Mark

• Mold Flash

• Corrosion

• Cracks

• Chips

• Overspray

• Inconsistent Textures

• Voids |

|

Lead Condition |

|

|

• Oxidation

• Re-Tinned

• Straightened

• Refurbished

• Bent Leads

• Tool Marks

• Lead Plating Quality

• Lead Alignment

• Lead Formation

• Lead Coplanarity

• Exposed Copper |

• Scratches on Leads

• Scoring

• Voids

• Plating Composition

• Physical Dimensions

• Residue

• Distorted

• Corrosion

• Chips in Leads

• Excess Solder Materia |

| |

|

|

|

|

|